Mirrors are essential in our daily lives. We all use mirrors at least once a day, Whether it’s during our morning routine in front of the bathroom mirror for applying makeup or shaving; When driving, we rely on the rearview mirror to check for traffic behind our vehicles, and dentists use mirrors to examine our teeth during dental procedures.

Given their importance, have you ever wondered about the history of mirrors and how they are made? Let’s explore this topic in today’s article.

Mirrors in History

Ancient Times

In ancient times, people first used natural materials like obsidian stone to create mirrors around 8,000 BC. These early mirrors were simply polished stones that could reflect a basic image. Evidence shows such polished stones are found in Anatolia (Turkey today) dating back to around 6000 BC.

By 4000 BC, metal(copper) mirrors were found in Mesopotamia (Iraq today), These mirrors were polished metal surfaces that offered improved reflectivity compared to earlier stones.

By 3,000-2,000 BC, bronze mirrors were crafted in China and Egypt.

Medieval Period

During the medieval period, metal-coated glass mirrors were invented.

In the first century AD, archaeologists discovered the first metal-coated glass mirrors in what is now Lebanon. The Romans later developed a technique for coating blown glass with lead. However, China advanced the coating process using mercury amalgams, beginning as early as 500 AD, as mercury provides a better reflection than lead.

The famous Venetian glass mirrors emerged in the 14th century. These mirrors were known for their clarity and quality. Artisans on the island of Murano perfected the art of using tin and mercury to coat glass, creating clearer reflections. By the 16th century, Venice had established itself as a hub for producing mercury-coated mirrors.

Modern Era

The modern era of mirrors began with the silvering process introduced by Justus von Liebig in 1835. This process involved spraying a thin layer of silver onto the back of a piece of glass, significantly improving the reflectivity and quality of mirrors.

In the 20th century, mirror making technology saw another advancement with the transition from silver to aluminum coating. Aluminum is now commonly used in the production of modern mirrors because it bonds well with glass and provides excellent reflective properties.

What Are Mirrors Made Out Of?

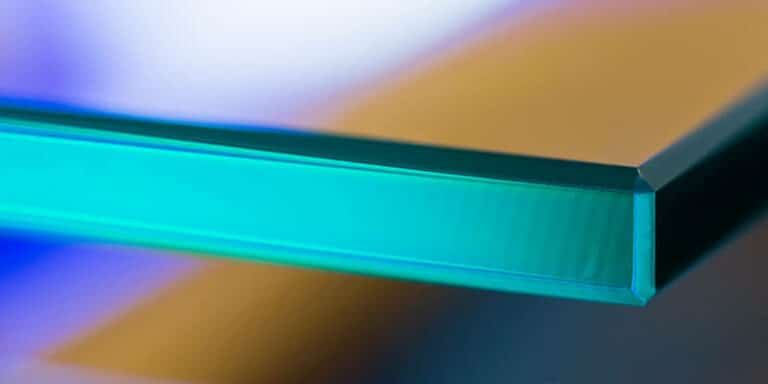

Mirrors start with high-quality glass, usually made from float glass or tempered glass. These types of glass sheets are known for their flatness and strength. The glass acts as the base material due to its transparency, rigidity, and smooth surface.

A metal coating is applied to make the glass reflective. Mercury, silver, or aluminum are commonly used for their excellent reflective properties, and sometimes gold is also used.

Additional materials may also be used:

- Copper often used as a protective layer over the silver or aluminum coating

- Non-toxic silver, used in some modern mirrors for safety and environmental concerns

Acrylic mirrors are another type, made from plastic rather than glass. They are lightweight and durable but less reflective than glass mirrors.

How Were Mirrors Made in the Past?

Polished Stone and Metal

In ancient times, mirrors were made from polished stones. Obsidian stone mirrors were some of the earliest examples. These mirrors were small, heavy, and typically used by the wealthy.

Around 2000 BC in China and 2900 BC in Egypt, people made mirrors from bronze. These were flat discs, often with handles made of wood, metal, or ivory. The bronze was polished until it could reflect an image.

Venetian Glass Mirrors

In the Renaissance period, Venetian artisans created high-quality glass mirrors. They backed the glass with a mixture of tin and mercury. This process made very reflective mirrors. The craftsmen in Venice kept their techniques secret to maintain a monopoly on the mirror market.

Glass Mirrors with Reflective Coating

By the early 19th century, a German chemist named Justus von Liebig developed a new method to create mirrors. He used silver nitrate to apply a thin layer of silver to the back of a glass sheet. This technique, known as silvering, vastly improved the quality and affordability of mirrors.

Here is a simple timeline for clarity:

| Time Period | Mirror Type | Materials Used |

| Ancient Times | Obsidian Stone | Obsidian |

| 2900 BC | Bronze Mirrors | Bronze, handles |

| Renaissance | Venetian Glass Mirrors | Glass, tin, mercury |

| 1835 | Silvered Glass Mirrors | Glass, silver |

These methods highlight the evolution of mirror-making from simple polished stones to sophisticated glass-backed mirrors.

How Are Mirrors Made Today?

Nowadays, mirrors are made by applying a reflective metal layer to one side of the glass. For example, a silver mirror is created by coating the glass with a layer of silver, a process known as the silvering process.

The silvering process begins with thoroughly cleaning and polishing the glass using non-mineral water, as minerals in water can damage the reflective metal layer. Next, tin chloride is applied to prepare the surface for coating, helping the silver nitrate solution to adhere to the glass.

A spray of silver nitrate solution mixed with ammonia is carefully applied to the glass, resulting in a chemical reaction that deposits a thin layer of silver on the surface.Once the silver layer is in place, a protective copper-free coating is added to prevent tarnishing. Multiple layers of paint are then applied to protect the reflective surface against scratches and unevenness. This type of mirror is also known as a copper-free silver mirror, which provides better corrosion resistance and is more eco-friendly, making it suitable for use as bathroom mirrors.

For more information on how mirrors are made today, you can watch the following video.

Modern mirrors can also use aluminum coating instead of silver. Aluminum is commonly used due to its cost-effectiveness and ability to provide high reflectivity.

For scientific research and specific applications, mirrors may have dielectric coatings like silicon oxides or silicon nitrides. These coatings enhance certain properties like reflectivity and durability.

What Chemical Processes Are Used to Make Mirrors?

The reflective layer of mirrors is produced by chemical reactions. Modern mirror making usually involves a silver layer or an aluminum layer.

So let’s take a look at the silvering process and the aluminizing process.

Silvering Process

- Silver Nitrate Reaction: This process starts with a chemical reaction between silver nitrate and reducing agents like glucose or ammonia.

- Reflective Silver Layer: The reaction produces a thin layer of metallic silver that is deposited on the glass. This layer is what makes the glass reflective.

- Protection: Often, a protective layer of copper is added to prevent the silver from tarnishing, ensuring the mirror lasts longer.

Aluminizing Process

- Vacuum Deposition: In another method, an aluminum coating is added to the glass. This involves placing the glass in a vacuum chamber.

- Evaporation: Aluminum is evaporated in the chamber, and it condenses onto the glass surface.

- Strong Adhesion: This ensures the coating is evenly distributed, providing durable and highly reflective aluminum-coated mirrors.

Frequently Asked Questions

What type of metal is used in the composition of mirrors?

Silver and aluminum are the most commonly used metals for the reflective coating on mirrors. Silver provides excellent reflectivity, while aluminum is often used for more cost-effective options. Different applications may require different metals for the coating.

What are the historical methods used for producing mirrors?

In ancient times, mirrors were often made from polished metal such as bronze or copper. These metal sheets were polished until they were smooth and reflective. Such mirrors were primarily used by the wealthy and ruling classes due to the labor-intensive process.