Mirror Etching Design

Making your design unique, elegant and adding a tinge of luxury

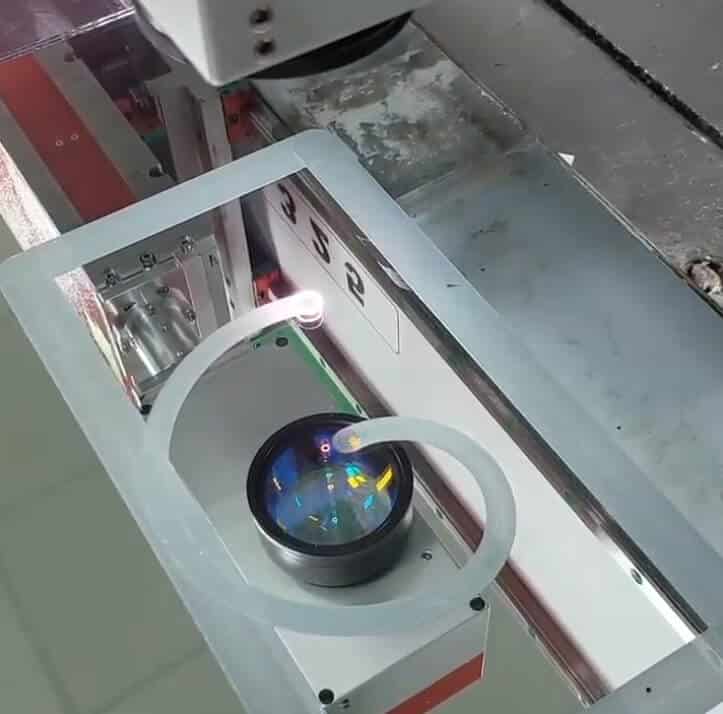

Laser Etching

LED Mirror needs to remove the reflection layer so that the light can go through the glass to illuminate your face. Some fancy designs also require lighted patterns on their mirrors.

With high-power laser etching machines, you can have those unique designs on your mirrors very quickly.

Laser etching can not only increase productivity but is also cost-effective. Contact Okay Mirror today for project support.

Sandblast Etching

Sandblast etching is traditional workmanship for lighted mirrors, it requires more time and cost for manufacturing, but it has some advantages over laster etching.

First, if the reflection layer is thick, sandblasting will be an ideal solution. Second, its etching effect can be better than laser etching, the light that goes through sandblast etching will be more soft and uniform.

Inquiry

Looking for custom lighted mirrors for projects? More questions about LED mirrors or medicine mirror cabinets?

Leave your messages here, Let’s talk more.