Quality Control

Quality Control

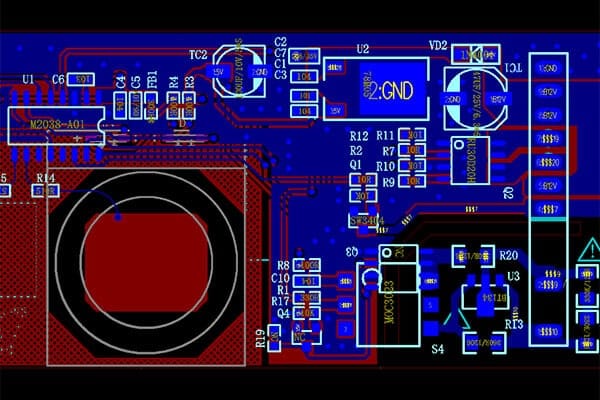

Electrical Circuit Design

electrical circuit design is a foundation for the whole system. the quality of the hardware's circuit may affect the performance of the LED mirrors. so OkayMirror's engineers treat every design phase seriously, from requirement analysis, schematic design, and PCB design to file processing.

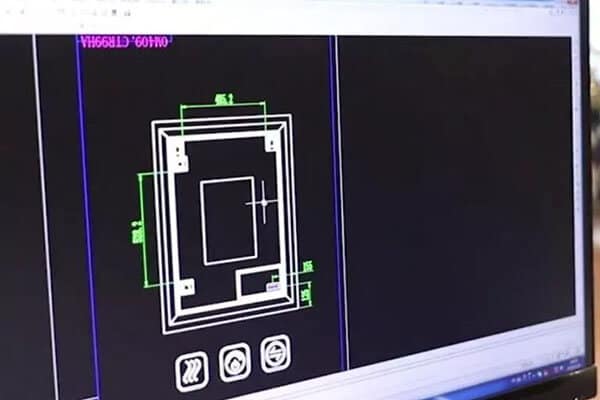

Product Structure Design

structure design is another very important part of the LED mirror engineering design. better structure will generate better lighting effects and appearance. structure engineer should deal with material quality checks, structure validation, shape, rigidity, precision, tolerance, heat treatment, and finish workmanship.

Integrated Light Analysis Sphere

integrated light analysis sphere is used to choose qualified lighting sources, it can check voltage, frequency, current, power, power factor, optical flux, optical effect, correlated color temperature (CCT), development index (RA), and so on.

Aging Test

both electric components and light sources are required to pass aging tests before delivery. it can help our factory find out the potential quality problem of LED lighting sources or electric components, this process usually takes 24-48 hours according to different production lines.

Salt Spray Test

some mirrors will be used in an atmosphere with high humidity, such as bathrooms, washrooms, luxury vessels, etc., so a corrosion-proof test is required for quality control. the salt spray test machine is used to simulate this kind of environment to check and eliminate those unqualified raw materials and components.

Surrounding Temperature Test

this machine is used to simulate a real environment -- temperature and humidity -- where the mirror will be used. so as to check whether it can work normally. sometimes, engineers will also set it as an extreme situation to check if the products can work in extreme circumstances for some time.

EMC Test

EMC-RRB-Test, also known as the electromagnetic compatibility test, is a comprehensive evaluation of an electronic product's electromagnetic interference (EMI). it can check whether the working of the LED mirror will interfere with other appliances and cause annoying results

Hi-Pot Test

the voltage may not be stable in some extreme situations, the hi-pot test will apply a high voltage to components or materials to test if they can stand up to high voltage shock. by doing this we can check whether LED bathroom mirrors can meet safety standards.

Vibration Test

this machine is used to simulate the problems we have to face during the transportation period, some components will fall out due to vibration, and some products will be damaged because of the packaging. the vibration test machine helps us find out those problems and solve them before mass production.

Drop Test

well-packaged mirrors may fall to the ground accidentally during transportation. drop test machine is used to test the reliability of packaging in the QA lab by following the standards of ISTA-1A and 2A or FedEx 6A. engineers will improve the packing according to the testing data.

Inquiry

Looking for custom lighted mirrors for projects? More questions about LED mirrors or medicine mirror cabinets?

Leave your messages here, Let’s talk more.