Have you ever gazed through a window and marveled at the sheer clarity and resilience of the glass? Whether it’s the sparkling facade of a skyscraper or the simple jar holding your favorite jam, glass is an omnipresent yet often overlooked marvel in our daily lives.

This article is crafted for those curious about the intricate world of glass, seeking to understand its various forms and functionalities.

With an expertise honed through extensive research, we’ll delve into the diverse types of glass, addressing common pain points like selecting the right type for specific needs. Tailored for homeowners, designers, and anyone in between, this journey through glass types promises not only to inform but also to connect with your personal experiences and interests. Let’s build a rapport as we embark on this enlightening exploration, uncovering the beauty and versatility of glass in its many incarnations.

Engineering Properties of Glass

In order to easily understand the types of glass, let us take some time to review the glass properties first. Here are some key engineering properties of glass:

Optical Properties:

- Transparency: Glass is highly transparent to visible light, making it ideal for applications like windows and lenses.

- Refractive Index: The refractive index of glass varies depending on its composition, affecting how it bends light.

Mechanical Properties:

- Brittleness: Glass is brittle, meaning it breaks easily without significant deformation.

- Hardness: Glass is generally hard and resistant to scratching.

- Tensile Strength: The tensile strength of glass is relatively low compared to its compressive strength.

Thermal Properties:

- Thermal Expansion: Glass has a low coefficient of thermal expansion, which means it doesn’t expand or contract much with temperature changes.

- Thermal Conductivity: Glass is a poor conductor of heat.

- Heat Resistance: Some types of glass, like borosilicate, can withstand high temperatures without melting or deforming.

Chemical Properties:

- Corrosion Resistance: Glass is highly resistant to most chemicals and is impermeable to liquids and gases.

- Weather Resistance: Glass is resistant to weathering and can maintain its properties over time even when exposed to environmental elements.

Electrical Properties:

- Insulator: Glass is an excellent electrical insulator, making it suitable for use in electrical applications.

Acoustic Properties:

- Sound Transmission: Glass can transmit sound but can also be engineered to provide sound insulation in certain applications.

Environmental Properties:

- Recyclability: Glass is 100% recyclable without loss in quality or purity.

- Inertness: Glass does not react with other substances and does not release harmful substances, making it environmentally friendly.

These properties can vary based on the type of glass and its specific composition. For example, the addition of certain elements can alter its strength, thermal resistance, or optical clarity. This versatility makes glass a valuable material in industries ranging from construction and automotive to electronics and packaging.

Types of Glass

Glass is a versatile material used in various industries, and it comes in many types, each with unique properties and applications. Here are some common types of glass:

#1 Insulated Glass

- What is it?: Insulated glass units (IGUs) consist of two or more glass panes separated by a spacer and sealed at the edges. The space between the panes is filled with air or inert gases like argon or krypton, enhancing thermal insulation. The edges are typically sealed with a high-strength sealant to prevent moisture and air ingress.

- Applications: Widely used in windows for homes, offices, and high-rise buildings.

- Why and Special Features: Offers improved thermal performance, reducing heat loss in winter and heat gain in summer. It’s chosen for its energy efficiency and noise reduction capabilities.

#2 Vacuum Glass

- What is it?: Vacuum insulated glass is an advanced form of insulating glass. It comprises two panes separated by a microscopically thin gap, from which air is evacuated to create a vacuum. This vacuum gap dramatically reduces heat transfer due to conduction and convection, making it one of the most effective forms of insulation in a window product.

- Applications: Ideal for energy-efficient buildings, both in residential and commercial sectors.

- Why and Special Features: Provides exceptional thermal insulation, comparable to a wall, significantly reducing energy costs.

#3 Float Glass

- What is it?: Float glass is produced through a process where molten glass is poured onto a bed of molten tin. This process results in a glass with very flat and parallel surfaces. It’s a basic glass product that can be further processed into a variety of finished products like toughened or laminated glass.

- Applications: Basis for many types of glass products, including windows, mirrors, and car glass.

- Why and Special Features: Offers a smooth, flat surface with uniform thickness, perfect for various treatments and applications.

#4 Annealed Glass

- What is it?: Annealed glass is the basic product formed from the float glass process. After being formed, it is slowly cooled in a controlled environment to relieve internal stresses. This process makes it less prone to breakage than regular glass, but it can still shatter into large, sharp pieces.

- Applications: Used in double-glazed windows, picture frames, and some types of furniture.

- Why and Special Features: Provides a clear, distortion-free view and is the starting point for many other types of glass processing.

#5 Tempered or Toughened Glass

- What is it?: Tempered glass is made by heating annealed glass and then rapidly cooling its surfaces. This process puts the surfaces into compression and the interior into tension, significantly increasing its strength and changing its breakage pattern. It is about four times stronger than annealed glass.

- Applications: Used in shower doors, car windows, and as safety glass in buildings.

- Why and Special Features: When broken, it shatters into small, less harmful pieces, providing increased safety.

#6 Heat Strengthened Glass

- What is it?: Heat-strengthened glass is made using a similar process to tempered glass but with less extreme cooling. This results in a glass that is approximately twice as strong as annealed glass. Unlike tempered glass, it does not break into small granular chunks.

- Applications: Often used in double-glazing where additional strength is needed.

- Why and Special Features: Stronger than annealed glass but not as strong as tempered, it doesn’t shatter into small pieces.

#7 Laminated Glass

- What is it?: Laminated glass consists of two or more layers of glass bonded together with an interlayer, typically made of polyvinyl butyral (PVB) or ethylene-vinyl acetate (EVA). This interlayer keeps the layers of glass bonded even when broken, and its high-strength bonds provide additional security.

- Applications: Used in windshields, skylights, and architectural applications where safety and security are concerns.

- Why and Special Features: Maintains integrity when broken; the interlayer holds the pieces together, providing additional safety and security.

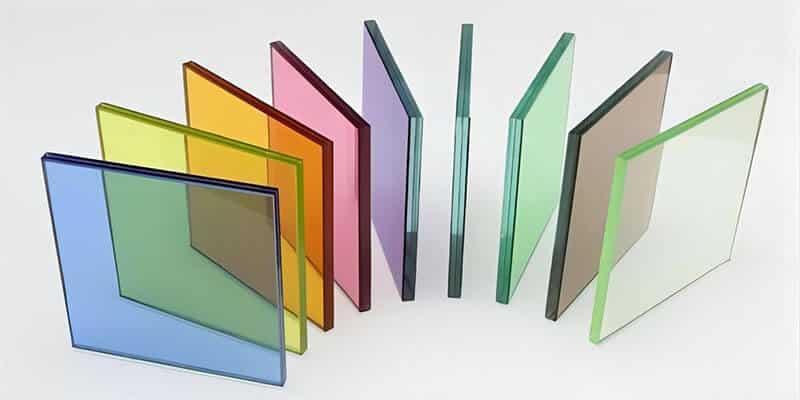

#8 Tinted Glass

- What is it?: Tinted glass is created by adding metal oxides to float glass during its production, giving the glass color as well as increased solar control properties. The tint can reduce glare and heat build-up from sunlight.

- Applications: Commonly used in automobiles, architectural facades, and decorative applications.

- Why and Special Features: Reduces solar heat gain and glare, improves aesthetic appeal, and offers privacy.

#9 Coated Glass

- What is it?: Coated glass involves the application of metallic or non-metallic coatings onto the glass surface. These coatings can be applied for various reasons, including improving solar control, increasing thermal insulation, and even adding aesthetic qualities to the glass.

- Applications: Used in energy-efficient windows and for decorative purposes.

- Why and Special Features: Enhances thermal and acoustic insulation, and can be tailored for specific optical properties.

#10 Painted Glass

- What is it?: Painted glass is essentially float glass that has been coated on one side with a high-quality paint. This paint is then heat-treated or cured, creating a durable and opaque colored finish.

- Applications: Used in kitchen backsplashes, wall panels, and in furniture.

- Why and Special Features: Provides a sleek, modern aesthetic and is available in a wide range of colors.

#11 Obscured Glass

- What is it?: Obscured glass is made by treating the surface of the glass to distort visibility through it. This can be achieved through methods like frosting, etching, sandblasting, or using adhesive films. The primary purpose is privacy while still allowing light through.

- Applications: Commonly used in bathroom windows, shower doors, and where privacy is needed.

- Why and Special Features: Offers privacy while still allowing light to pass through.

#12 Low-Emissivity (Low-E) Glass

- What is it?: Low-E glass has a microscopically thin, transparent coating that reflects long-wave infrared energy (or heat). Its primary function is to reduce the amount of heat that passes through the glass, making buildings more energy-efficient.

- Applications: Ideal for energy-efficient windows in homes and commercial buildings.

- Why and Special Features: Minimizes the amount of infrared and ultraviolet light that passes through glass, reducing energy costs.

#13 Mirrored Glass

- What is it?: Mirrored glass is made by applying a reflective coating to glass. This coating is generally made from silver or aluminum, applied on the back surface of the glass, providing a mirror finish to one side.

- Applications: Used in bathroom mirrors, furniture, and decorative elements.

- Why and Special Features: Provides a reflective surface, can be used for aesthetic and functional purposes.

#14 Wired Glass

- What is it?: Wired glass embeds a wire mesh within the glass during the manufacturing process. This wire mesh provides additional strength and is particularly effective in providing fire resistance, as it can prevent glass from shattering under high heat conditions.

- Applications: Used in fire-rated windows, skylights, and areas requiring additional safety.

- Why and Special Features: Offers fire resistance and maintains integrity under high temperature conditions, ensuring safety.

Each type of glass is tailored to meet specific requirements, whether it’s for strength, thermal resistance, optical clarity, or other special properties. This adaptability makes glass a crucial material in fields ranging from construction and automotive to art and design.